The XB7100 provides a fully automated inline inspection for multi-layer winding power batteries. It conducts a thorough examination of key elements in winding power and energy storage batteries, including the alignment of positive and negative electrode plates, large surface folds, and tab-pulling pins, thereby ensuring comprehensive quality control.

Premium X-ray Technology

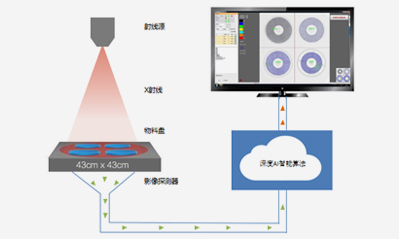

XB7100 employs the highly acclaimed Hamamatsu X-ray tube, recognized globally for its superior quality and precision. This high-end X-ray technology ensures accurate and detailed inspections of winding batteries.

Equipped with Seamark's self-developed algorithm software, XB7100 incorporates advanced algorithms for sophisticated analysis. This software enhances the machine's ability to detect intricate details within batteries, contributing to precise quality assessments.

Seamark provides unmatched customer support with a dedicated team of professionals. Their experienced Research and Development (R&D) specialists and after-sales service team offer prompt and efficient solutions. This commitment ensures seamless operation and reliability for businesses relying on XB7100 Winding Battery Inspection machines.

| Equipment Size | 5460mm*2600mm*2800mm |

| Beat | ≥26PPM and above (2 angles or 4 angles) |

| Excellence Rate | ≥99.5% |

| Overkill Rate | ≤1% |

| Underkill Rate | ≤1% |

| Equipment Failure Rate (DT) | ≤2% |

| Repeated Test Accuracy | ≤40um (standard piece measurement) |

| Average Failure Interval (MT BT) | ≥8H |

| Method of Incoming Materials | Incoming materials from logistics line |

| Radiation Safety Standard | ≤1μSV/hr |

| X-ray Tube | Voltage: 40-90KV/40-130KV; Current: 1 0 - 2 0 0 u A / 1 0 - 3 0 0 u A |

| Receiver | Flat panel detector |

| Photo Taking Time | ≥0.7S |

| Model Change Time | The model change time of old varieties ≤ 2 hours/person; the model change time of new varieties ≤ 4 hours/person |

| Compatible Range | Height: 70~220mm; Width: 80~260mm; Thickness: 5~25mm (or customize all models on the market) |

| Inspection Content | Overhang, Large area fold, Tab fold |

EN

EN

es

es  ko

ko  de

de  it

it  ru

ru  pt

pt  ar

ar  vi

vi  th

th  pl

pl