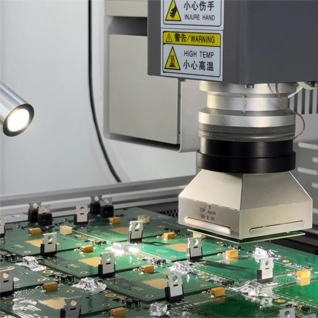

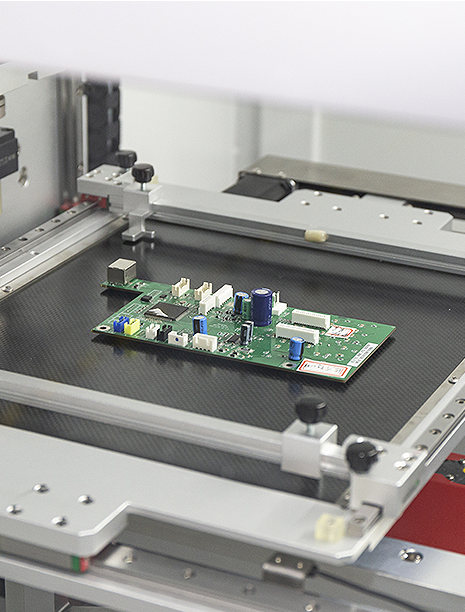

X-ray Inspection technology is now considered standard in SMT and EMS production. It is now the critical and essential step in ensuring quality and functionality in all applications and particularly in medical, aerospace, military, automotive applications.

Seamark provides a robust , reliable and high performance selection of systems in this arena.

We have 2.5D and 3D X-Ray inspection that can help you inspect wire bones, through-hole, HIP, bridging, voiding , and solder quality among many capabilities.

We also offer an on-line Inspection solution.

For the LED field, our X-Ray PCB inspection systems can be used to look at the device packages. The voids, gaps, or broken bonding wires can be detected to allow you to avoid potential problems, and expand the lifespan of your product.

For batteries and capacitors, our industrial X-Ray can be used to inspect overlapping, contact of tabs, and other defects.

Contact us to check what defects you would like to inspect.

EN

EN

es

es  ko

ko  de

de  it

it  ru

ru  pt

pt  ar

ar  vi

vi  th

th  pl

pl