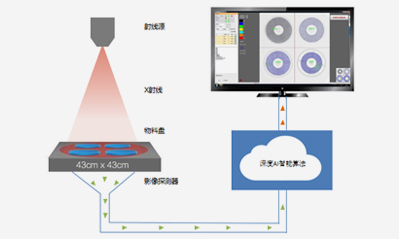

The Seamark XB5100 X-Ray inspection machine, equipped with expandable inspection capabilities such as plate fold and tab fold, and flat panel detector image acquisition technology, is an excellent choice for inspecting winding process-type batteries in the lithium battery industry. This X-Ray inspection system is well-suited for examining a variety of batteries, including aluminum shell batteries, cylinders, buttons, energy storage/power winding, and lithium digital soft packs.

High Configuration

Adopt the Hamamatsu X-ray tube, which is one of the best X-ray tubes around the world.

Equip with Seamark Self-developed algorithm software.

Professional R&D and after-sale service team that can provide in-time solutions.

| X-ray Tube Parameters | |

| Tube Type | Reflective Sealed Micro-Focus Ray Source |

| Tube Voltage Range | 40-90KV/40-130KV |

| Tube Rurrent Range | 10-200uA/10-300uA |

| Maximum Output Power | 8W-39W |

| Micro Focus Size | 5-15um |

| Receiver Parameters | |

| Flat Panel Type | Amorphous silicon flat panel detector (optional) |

| Pixel Matrix | 1536*1536 |

| Field of View | 130mm*130mm |

| Resolution | 5.8Lp/mm |

| Image Frame Rate (1x1) | 20fps |

| Ad Conversion Bits | 16bits |

| Detection Efficiency And Accuracy Parameters | |

| Repeated Test Accuracy | 40um (standard piece measurement) |

| Detection Speed | ≥1.0/detection point (excluding loading and unloading time) |

| Stage Parameters | |

| Maximum Sample Size | 420mmX420mm |

| Loading Capacity | ≤8Kg |

| Other Parameter | |

| Control System | Industrial computer Win10 (64-bit) |

| International Radiation Safety Standards | ≤1μSV/hr |

| Equipment Size/Weight | 1220*1260*1900mm, About 1000Kg |

| Power Supply | AC220V 10A, 50-60Hz |

EN

EN

es

es  ko

ko  de

de  it

it  ru

ru  pt

pt  ar

ar  vi

vi  th

th  pl

pl