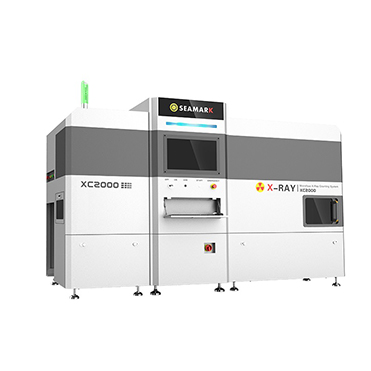

Our X Ray SMD component counter , an advanced solution designed to streamline the inspection and counting of various chip components.

The X-ray reel counter machines produced by Seamark have the characteristics of high performance, cost-effectiveness, long lifespan, user-friendly software, simple maintenance, high definition inspection image with special tilt which make our machines can meet different category products inspection needs. Additionally, our x ray counting machines are of guaranteed quality and comply with strict CE and FDA standards.

Besides standard X-ray component counter, we also provide customized solutions to meet your special inspection requirements.

Welcome to order!

Key features of a high-quality X-Ray component counter include:

High Accuracy and Speed: Ability to quickly and accurately count large quantities of components.

Advanced Imaging Software: Software capable of identifying different types of components and filtering out noise.

User-Friendly Interface: Easy-to-use interface with minimal training required.

Versatility: Ability to handle various component sizes, shapes, and packaging types.

Data Integration: Integration with inventory management systems for seamless data transfer.

Robust Construction: Durable hardware capable of withstanding industrial environments.

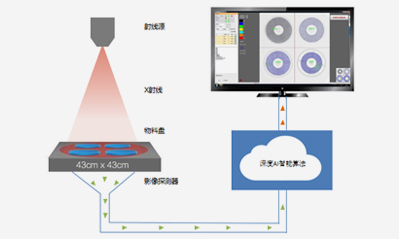

An X-ray SMD component counter is a machine used to count and verify the number of SMD components on a reel or in a batch. These counters use X-ray technology to see through the packaging and accurately count the components without opening the packaging. This is particularly useful in electronics manufacturing and quality control to ensure that the correct number of components are present and to prevent errors in inventory management.

An X-Ray component counter uses X-ray imaging technology to count components on reels, trays, or loose in bulk. The X-ray system generates an image of the components, and software algorithms analyze this image to identify and count each component based on its shape, size, and material density. The process is quick, accurate, and non-destructive, making it ideal for inventory management in manufacturing and electronics assembly.

The machine is capable of handling a variety of chip components, including resistors, capacitors, crystals, LEDs, diodes, transistors, and various multi-pin integrated circuits (ICs)

EN

EN

es

es  ko

ko  de

de  it

it  ru

ru  pt

pt  ar

ar  vi

vi  th

th  pl

pl